|

|

|||||||||||||||||||||||||||||

|

Chemical and Process Engineering |

|||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||

|

|

|

|

|

|

|

||||||||||||||||||||||||

|

PTTPE LDPE Project |

|||||||||||||||||||||||||||||

|

|

|

|

|

|

|

||||||||||||||||||||||||

|

Low Density Polyethylene |

|

|

|

Client: Simon-Carves |

|||||||||||||||||||||||||

|

|

|

||||||||||||||||||||||||||||

|

2007/2008 |

Senior Process Engineer |

||||||||||||||||||||||||||||

|

|

|

|

|

|

|

||||||||||||||||||||||||

|

|

|

|

|

|

|

||||||||||||||||||||||||

|

Project Background |

|

|

|

|

|

||||||||||||||||||||||||

|

|

|

|

|

|

|

||||||||||||||||||||||||

|

Simon-Carves

Limited in co-operation with Toyo-Thai Corporation Ltd (TTCL) were awarded a contract by PTT Polyethylene Co Ltd (PTTPE)

for the design, supply and construction of a LDPE (Low Density Poly Ethylene)

plant in Map Ta Phut, Rayong

Province, Thailand. The plant capacity is 300,000 tonnes per annum. |

|||||||||||||||||||||||||||||

|

|

|

|

|

|

|

||||||||||||||||||||||||

|

|

|

|

|

|

|

||||||||||||||||||||||||

|

Summary of Process |

|

|

|

||||||||||||||||||||||||||

|

|

|

|

|

|

|

||||||||||||||||||||||||

|

The process (from Basell Polyolefines GmbH) is based on a high pressure tubular reactor. Ethylene, produced at the adjacent petro-chemical complex, is supplied to the plant and compressed using hyper-compressors to a pressure of around 3000 bar. |

|||||||||||||||||||||||||||||

|

|

|

|

|

|

|

||||||||||||||||||||||||

|

|

|

The

compressed Ethylene gas is preheated and passed through a number of tubular

reactors into which organic peroxides are injected to initiate the reaction.

The reactors are double pipe units with pressurised hot water flowing in the

annuli. The polymerisation reaction is highly exothermal and the energy

removed from the reaction is converted in to steam at various pressures for

use within the LDPE plant and elsewhere on complex. Excess unused ethylene is

separated after the reactors and recycled to the reactor feed system. The

polymer melt is mixed with additives in an extruder to yield the final

product. Some ethylene is carried forward through the extruder and the

pellets are degassed with air during intermediate storage prior to being sent

to final product storage. Polymer properties are controlled by the initiator, pressure, temperature profile and co-monomer content. |

|||||||||||||||||||||||||||

|

|

|

|

|

|

|

||||||||||||||||||||||||

|

|

|

|

|||||||||||||||||||||||||||

|

Specific

Responsibilities |

|

|

|||||||||||||||||||||||||||

|

|

|

|

|||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||

|

|

|

|

|

|

|

||||||||||||||||||||||||

|

|

|

|

|

|

|

||||||||||||||||||||||||

|

Extrusion |

|

|

|

|

|

||||||||||||||||||||||||

|

|

|

|

|

|

|

||||||||||||||||||||||||

|

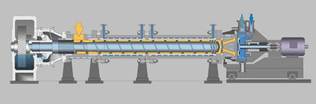

Extrusion

takes the molten polymer and converts it in to pellets. As part of this

process, the bulk of the residual dissolved ethylene is removed by reduction

of pressure in the feed zone of the main extruder. The

degassed polymer is then forced by the screw of the main extruder (driven by

a 3.4 MW motor) through the holes in a die plate into the granulator where it

is rapidly quenched with water, cut in to pellets by rotating knives and

transported away to the downstream pellet dryer by the this water. Polymer properties are adjusted by the addition of master batch polymer injected in to the main extruder from a satellite extruder and by the injection of liquid additives in to the main extruder. |

|

|

|

||||||||||||||||||||||||||

|

|

|

|

|

|

|

||||||||||||||||||||||||

|

Courtesy of KM Berstorff |

|

A pressurised water system is used to control the

temperature of the main extruder barrel. Steam and cooling water are also used

to control other temperatures in the extrusion process. Process Engineering of the extrusion area required

ensuring the extruder vendor proprietary design was integrated in to the rest

of the process, especially with respect to detailed checking of interlocks

and emergency shutdown requirements for which there are around 200 inputs. |

|||||||||||||||||||||||||||

|

|

|

|

|

|

|

||||||||||||||||||||||||

|

|

|

|

|

|

|

||||||||||||||||||||||||

|

Passive Fire Protection A philosophy was written to define the

requirements for the passive protection of process equipment and structures

from the effects of fire (as opposed to active protection using fire-fighting

/ extinguishing media such as water). The main references for the philosophy were: q

Licensor’s health safety and environmental

criteria, q

API 2218 “Fireproofing practices in petroleum and

petrochemical processing plants”. q

Dutch Committee for the Prevention of Disasters;

PGS 8E (formerly CPR 3E) “Storage of Organic Peroxides” q

Owner specifications. Experience gained on other Simon-Carves LDPE

projects was also applied. |

|

The extent of fireproofing was shown on

layout and elevation drawings. This addressed protection of the following: ·

Plant structures. ·

Supporting structural parts of vessels and

equipment. ·

Pipe racks and pipe supports. ·

Shut down / blow down valves and actuators. ·

Safety critical Instrument and electrical cabling. |

|||||||||||||||||||||||||||

|

|

|

|

|

|

|

||||||||||||||||||||||||

|

|

|

|

|

|

|

||||||||||||||||||||||||

|

Documents Produced P&IDs for Degassing extruder, Extruder motor

(air purged), Satellite extruder and solids feed system, Granulator (pelletiser),

Pressurised hot water system, Lube oil system, Hydraulic power pack, Liquid

additives preparation and dosing. Passive Fire Protection Philosophy. Fire zone drawings. Specialist Software "InTools" for creating process

specifications for instrumentation. "PDMS Reality Review" for 3D plant layout visualisation. "TASC5" for shell and tube heat exchanger design. |

Hazards Considered Nitrogen asphyxiation Flammable liquids Explosive gases and vapours Design Reviews Model Reviews HazOp Studies SIL assessment. Problems Identified and

Solved Thermite reaction issues. Nitrogen asphyxiation risk. Flash steam emissions. Safety relief scenarios. Liaison Other Engineers; Process, Control, Mechanical, Piping. |

||||||||||||||||||||||||||||

|

|

|

|

|||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||